Nosab Gürgen Cadde No:4 Ni̇lüfer / Bursa - Türki̇ye

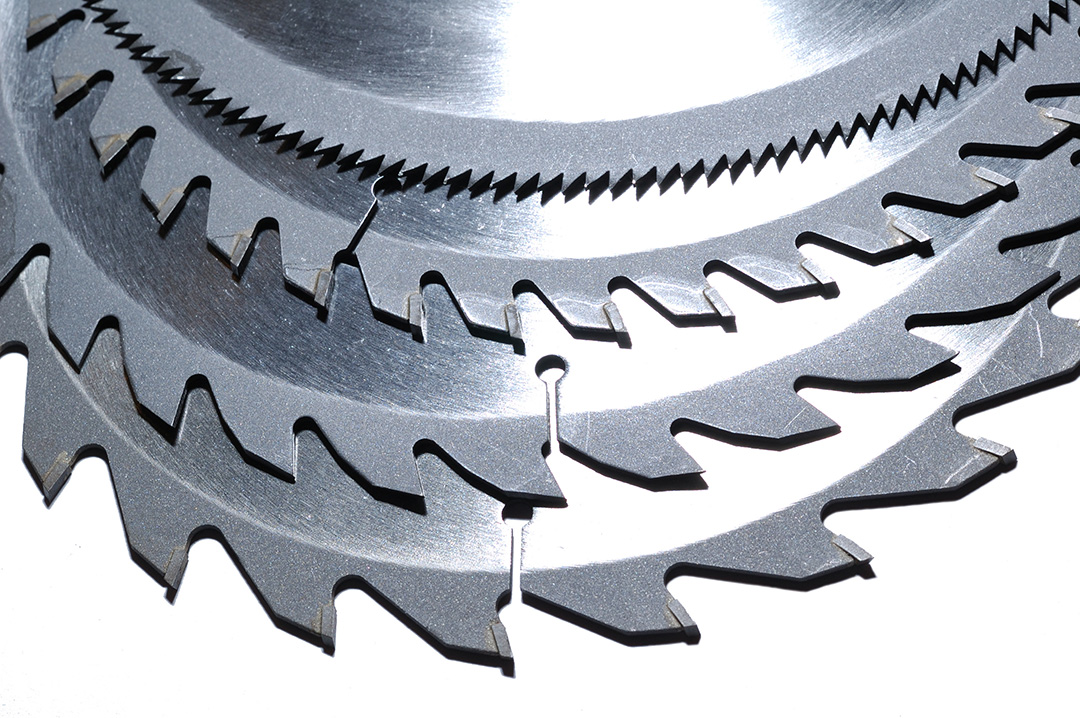

Cold Saw Blades

Cold Saw Blades

Tips For Buying And Changing a Cold Saw Blade

A cold saw uses a circular saw blade to cut metal. It got its name from the fact that these saws transfer the heat back into the blade rather than into the object being cut, thereby leaving the chopped material cold unlike an abrasive saw, which heats up the blade and the object cut.

Typically high speed steel (HSS) or tungsten carbide-tipped circular saw blades are used in these saws. It has an electric motor and a gear reduction unit to control the speed of the saw blade rotational speed while maintaining the constant torque, which will increase its efficiency. A cold saw produces minimum sound and no sparks, dust or discoloration. The materials that has to be cut is clamped mechanically to ensure a fine cut and to prevent dislocation. Cold saws are used with a flood coolant system that will keep the saw blade teeth cooled and lubricated.

Choosing the right cold saw blade is very important in ensuring the best quality cut. There are special saw blades to cut wood or metal sheets and pipes. Here are some tips to remember while buying cold saw.

Blade Material: There are three types of cold saw blade basically including carbon steel, high speed steel (HSS) and tungsten carbide tip. Carbon blades are considered the most economical of all and are preferred for most basic cutting jobs. However HSS blades are more durable and long lasting than carbon steel while Tungsten carbide blades have the fastest cutting speed and life span of the three types.

Thickness: The thickness of cold saw blades is related to the diameter of the saw's mounting wheel. For a smaller wheel of 6 inches, you may need only a blade of 0.014 inches. Thinner the blade more will be the lifespan of the blade. Make sure to find the correct diameter for the blade from the user's manual or consult the local supplier for these essential information.

Tooth Design: It is better to choose standard tooth designs for fragile materials and general-purpose cutting. Skip-tooth blades are used for the smoothest and fastest cuts for massive objects. Hook-tooth units are typically used for cutting thin metals like aluminum.

Pitch Rating: It is measured in the unit of teeth per inch (TPI). The optimal TPI is between 6 to 12, depending on the material used. While soft materials like aluminum need fine blades with a relatively high TPI, thick materials require hard blades with a low pitch.

Tooth Set Pattern: Regular blades have single alternating teeth on either sides of the blade. These blades ensure the most uniform cuts and are well suited for cutting curves and contours. Wavy pattern blades with many adjacent teeth set arranged on one side of the blade, which forms a wave pattern with the next group of teeth set to the opposite side are long lasting. Wavy patterns are used mostly on delicate materials.

Materials Cutting Guide

When cutting materials other then mild steel other variables come into play.

Mild Steel

Optimal cut quality and blade life is achieved by cutting at a speed of approximately 100 to 125 SFM (surface feet per minute)

Stainless Steel

The person selecting the blade must multiply the tooth count in the above chart by 1.2 to ensure proper blade life and cut quality. Optimal cut quality and blade life is achieved by cutting at a speed of approximately 70 SFM (surface feet per minute)

Aluminum

The person selecting the blade must multiply the tooth count in the above chart by .75 to ensure proper blade life and cut quality. Optimal cut quality and blade life is achieved by cutting at a speed of approximately 300 SFM (surface feet per minute)

Solids

Solids also have there quirks when it comes to cut quality and blade life. Below is a chart to help you pick the best blade for your solid application. Remember that the same rules for blade speed apply to solids as they do to tube and pipe.

One other important idea to consider when trying to optimize blade life is the type of cold saw you are purchasing. A semi-automatic cold saw with controlled decent of the head will always provide longer blade life over a manually operated saw.